Application

It is applied to oil wells with sand production or pulverized coal, specially used for sand-rich environments

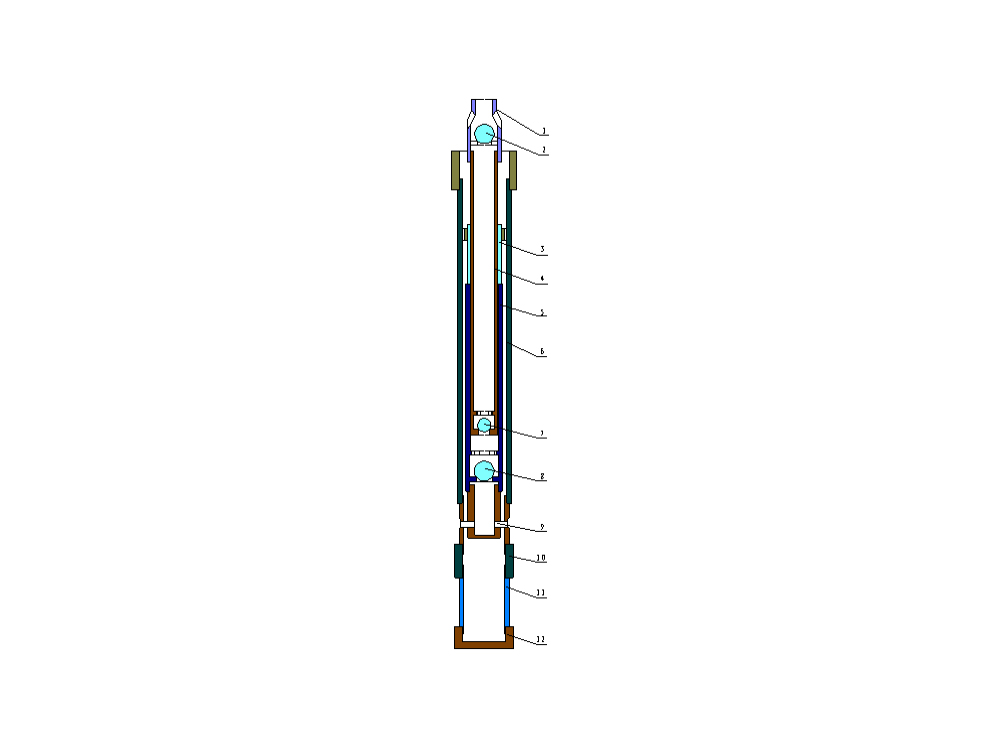

Structure

As the figure shows, the upper oil outlet valve is always outside the barrel.

1---Forced upper oil outlet cage

2---Upper oil outlet valve

3---Short barrel

4---Long plunger

5---Barrel extension tube

6---Sand settling outer cylinder

7---Lower oil outlet valve

8---Oil inlet valve

9---Bridge oil inlet hole

10---Coupling

11—sand settling pipe

12—Plug

Working Principle

1. Oil pumping: Similar to common oil well pumps, the fluid in well enters the pump through the bridge oil inlet valve (8) in the swabbing process and then will be discharged to the top of pump through long plunger (4).

2. Sand control: The sand enters the sand settling pipe 11 below the pump through the annular space between the sand settling outer cylinder 6 and pump barrel 3. And some sand deposited in the barrel will be brought outside of pump by oil flow due to the short pump barrel. If pumping is interrupted midway, the sand in the fluid in the tubing at top of pump will be also deposited in the sand settling pipe so as to avoid sand plug and sand burial.

Product features

1. High pump efficiency: As the top plunger travelling cage is always outside the barrel, the oil outflow section is free from the limit of the barrel bore diameter. As a result, the oil outflow resistance is smaller than that of common pumps. The pump efficiency is high.

2. Long service life: No fluid exists between the barrel and plunger. It can avoid sand plug, wearing or erosion effectively. So the pump’s service life is improved a lot. Meantime the overbridge external pipe can avoid the force deformation of barrel and pump sticking.

3. Outstanding comprehensive mechanical performance :The long plunger is processed by integral spray welding.The inside surface of pump barrel is chrome plated. The valve seat material is hard alloy. So that enables high resistance of abrasion, corrosion and erosion.

Application of forced top oil outlet cage: As the top oil outlet cage is not limited by the pump bore diameter, the wall thickness increases, which improves the intensity a lot. So that it makes up the easy fracture defect of conventional pump’s oil outlet cage because of the thin wall.

Technical Parameters

公称直径 Nominal diameter(mm) | 冲程范围 Stroke range(m) | 油管联接螺纹 Tubing connection thread (上/下)(upper/lower) | 抽油杆联接螺纹Sucker rod connection thread(mm) | 柱塞长度 Plunger length (m) | 最大外径 Max.OD(mm) |

φ32 | 2.1~5.1 | 27/8TBG | φ19/φ22 | 3.3~6.3 | φ89.5 |

φ38 | φ107 | ||||

φ44 | φ107 | ||||

φ56 | 31/2TBG/27/8TBG | φ107 |

ADD:Room 610, Fortune Plaza, Yungang Road, Aviation Economic Zone

ADD:Room 610, Fortune Plaza, Yungang Road, Aviation Economic Zone

PHONE:+86 156 1779 7655 ; +86 187 9070 1558

PHONE:+86 156 1779 7655 ; +86 187 9070 1558

TEL:+86 371 85304855

TEL:+86 371 85304855