Electric Submergible Pump System

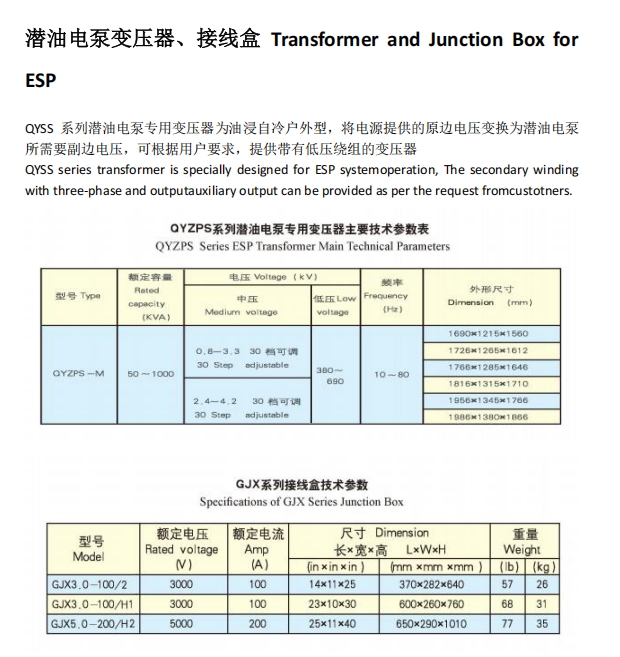

An electric submergible pumping system consists of three parts,which includes surface part,middle part and downhole ESP.Surface part mainly includes transformer,switchboard,junction box,wellhead and surface cable . Middle part is power cable and cable extension which connect surface and downhole equipment and provide motor with power.Downhole part is the main part of the system which includes electric submergible motor, protector, gas separator and multi-stage centrifugal pump,

Fiveseries ESP pump Powerlift can provide,338/375、400/456、513/540、538/562ESP system is applicable to the production casing of 4-2/z" and aboveand the reservoir temperature is up to 150'C.

Capacity:150-11000BPD(20-1600m3/d)

Head:<14760FT(4500m)

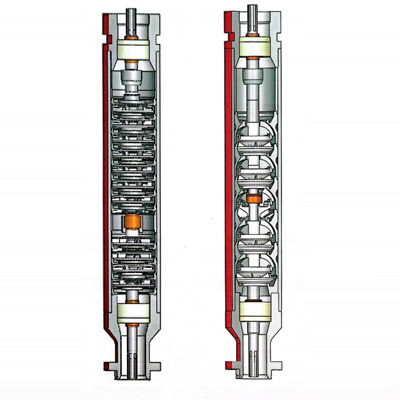

Pump

The Pumps are multistage centrifugal pumps for use with casings above 41/2”.Their discharge at50 Hz varies from 20 m3/d to 1600 m3/dand greater discharge can be obtained by usingrequency converter.We have adopted advanced CAD designing in the stages of pump which,as a result,have obtained high single stage lift and high efficiency.The Pumps are assembled in three

types of complete float,complete compresslve and half float,,and with a structure of radial flow and mixed flow. The various categories such as standard pump , abraision resistant and

anti-corrosion pump are applicable to different well condition.

You only need to give us the required hydraulic property of the pump , such as flow, head,efficiency and the main dimensional parameters of mounting to get a best produce from us.There

are options of differed materials for pump stages according to different well conditions:Ni-resist,high-chrome cast iron,copper aluminum alloy,stainless steel.We can supply the pump for

well with high sand and high gas content according to customer’s requests.The various categoriessuch as standard pump,Compression pump,anti-corrosion pump ,abraision resistant pump and AR Modular pump are applicable to different well condition。

Gas Separator

In order to ensure normal and continuous working of the centrifugal pump in gas-containing oil wells,An oil-gas separator is usually installed between the protector and the pump. Intake, gas separator and high efficiency gas processor can be equipped depending on the different gas content in gassy well. The gas separator type is distinguished into gravity and rotary , and the category is divided into standard,abraision resistant and anti-corrosion-proof.

For oil wells with high gas content double-section separator is used in order to ensure effective separation of free gas. Special separator can be used in high-sand wells and you will get a satisfactory result. The model in the table is standard equipment,and we can supply tabraision resistant and anti-corrosion-proof according to customer’s requests.

Protector

The protector is set between separator or intake and motor in ESP unit.Except for the connection function,the following is the main features:

1、Seal the power output end of the motor shaft to prevent well fluid from entering into the motor;

2、 Balance pressure between the casing annular space and inside the motor;

3、Balance axial force for the pump shaft and the separator shaft;

4、Adapt motor oil inside motor for expanding and contracting.

Protector type include labyrinth chamber ,rubber bag chamber and combined chamber, and the category includes standard,high load and anti-corrosion-proof。We can equip different heating resistant protector according to the heating resistant degree of the motor.

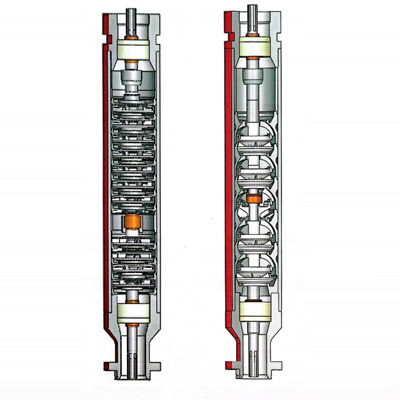

Submersible Motor

The submersible motor is a three-phase, squirrel-cage, induction type motor,and its rated revolution speed is 2850 RPM at 50HZ.

The submersible motor is vertical suspended construction, it is airtight with oil-immersed method,interior of the motor is completely filled with special lubricant as lubrication,insulatior

and thermal conduction.

Because the submersible motor is limited in varying well-gore,various series and sizes of the submersible motor are designed in order to meet requirements of different oil wells.It

also can be singer,double or multiple sections tandem according to the different power. Our company can produce 375 series、456 series、540series and 562series of submersible

motors.we can produce the resistant ESP for 120C,150℃and 150℃well temperature.

Motor is applicable to the casing of 4'/₂"、5"、5'/"、7"、95/8" and above ;

Operating voltage:140V一3600V

Operating current:14A104A

Rated RPM: 2850r/min@50Hz(3420r/min@60Hz)

Temperature grade:120℃、150℃、180°℃、

Comply with national standards:GB/T16750-2008:

375.456.540.562---- motor Series

E-----motor code(Special-shaped guide rod rotor motor series products)

Table for carbon steel product drawing number,can provide stainless steel products

ADD:Room 610, Fortune Plaza, Yungang Road, Aviation Economic Zone

ADD:Room 610, Fortune Plaza, Yungang Road, Aviation Economic Zone

PHONE:+86 156 1779 7655 ; +86 187 9070 1558

PHONE:+86 156 1779 7655 ; +86 187 9070 1558

TEL:+86 371 85304855

TEL:+86 371 85304855